MORE THAN JUST A GOOD IMPRESSION SINCE 1989

Sharper Image Engravers, Inc. is your resource for high-quality flexographic platemaking.

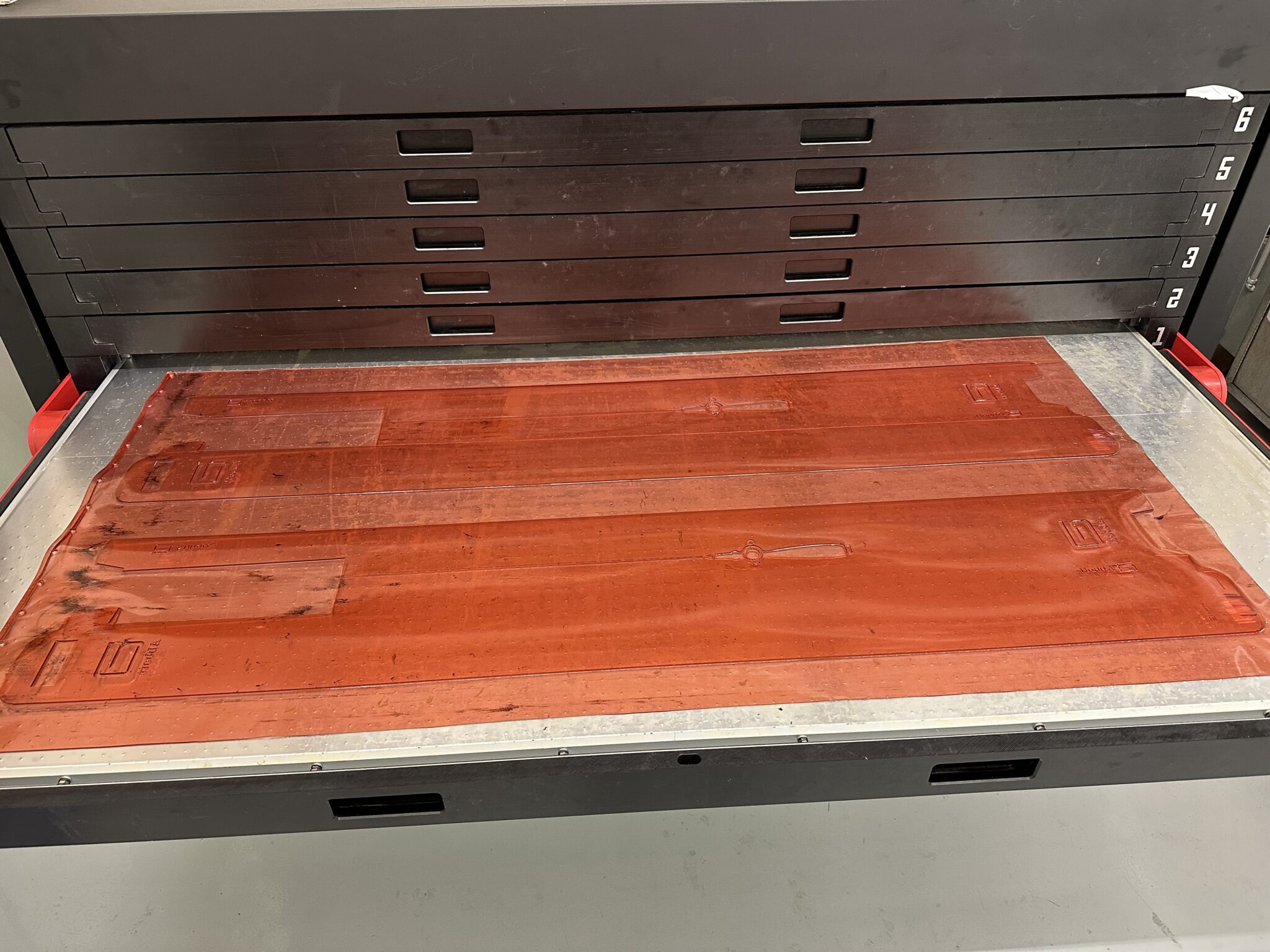

Let’s ConnectSince 1989, Sharper Image Engravers has led the way in flexographic platemaking. We introduced one of the first liquid photopolymer flexo platemaking systems to the Chicago area, and were leaders in establishing photopolymer technology as an industry standard, making molded rubber all but extinct. Our 16,000 square foot facility features state-of-the-art flexographic platemaking equipment, and our Sharper Image Engravers team consists of more than thirty highly skilled professionals. Each year, our sales continue to grow, as we consistently surpass our customers’ expectations with an outstanding product, exceptional value, and service that is second to none.

Sharper Image Engravers, Inc. is your resource for high-quality flexographic platemaking.

Let’s Connect